Sample Cup Series

Sample cups are subjected to strict quality control.

Low elution levels (All sample cup types)

Acetonitrile and an HPLC mobile phase (shown below) were placed separately into sample cups, and the cups were then sealed and left to stand for 40 hours. The contents of each cup were then analyzed to verify the presence or absence of eluted components (see chromatograms on the right).

Analytical conditions

Column:

ULTRON VX-ODS 5 μm 150 x 4.6 mm

Mobile phase:

10 mM Phosphate buffer (pH 3) /

acetonitrile: 1/1

Detection: UV-267 nm 1.0 x 10-2 AUFS

Injection volume: 100 μL

High levels of airtightness (All sample cup types)

On sealing ethanol in sample cups and heating the cups to 45 degrees Celsius, caps did not come unsealed due to the vapor pressure of the ethanol (approximately 20 kPa), and no leaks were observed.

Sample Cups ⅠA, ⅡA

Features

- Caps are made from polyethylene with slits, allowing for easy needle insertion.

- Cups are made from high quality polypropylene.

- The external dimensions of these sample cups are 12 mm I.D. x 32 mm (de facto world standard size). Cups conform to Shimadzu SIL autosamplers.

- 2 volumes available: 200 μL low volume and 1.5 mL standard volume.

Sample Cups ⅠB, ⅡB

Our sample cup range now includes brown sample cups designed to prevent deterioration of samples due to sunlight and UV radiation. These sample cups do not use inorganic colorants, and keep sample adsorption to a minimum in comparison with conventional brown vials thereby improving reproducibility. They have also passed elution tests.

Features

- No sample deterioration: Prevent the deterioration of samples due to sunlight and UV radiation.

- High reliability: Cups are made from high quality polypropylene.

“Elution” problems common to plastic containers, and “sample adsorption” problems common to brown vials have been reduced to negligible levels.

Dimensional accuracy of cups has been improved in order to enhance air tightness. - Easy needle insertion: Caps include built-in septa made from soft polyethylene that are provided withslits, enabling easy insertion of needles.

- The external dimensions of these sample cups are 12 mm I.D. x 32 mm (de facto world standard size). Cups conform to Shimadzu SIL autosamplers.

- 2 volumes available: 200 μL low volume and 1.5 mL standard volume.

- Economical: Economically priced with disposability in mind. Both varieties are available in lots of 1,000, at 42 yen per cup.

Centrifuge Sample Cups ⅤA, ⅤE (translucent)

No need to transfer centrifuged samples to separate vessels, enabling reductions in sample preparation times as well as costs!!!!

Sample Cup VE

After centrifuging of a sample, the conical protrusion at the bottom of the sample cup prevents the resuspension of precipitates, thereby allowing these sample cups to be used directly in HPLC autosamplers without the need for transferring samples to separate vessels.

Sample Cup VA

Centrifuge filter devices * can be attached to these sample cups. After filtration of samples using a centrifuge, these sample cups can be used directly in HPLC autosamplers without the need for transferring samples to separate vessels.

* PALL GHP NANOSEP MF 0.45 μm centrifuge filter devices

Spacers (for 12 mL centrifuges)

Sample Well Plate Series

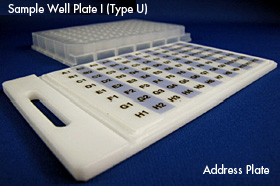

Sample Well Plate Ⅰ (Type U) & Well Caps

Features

Sample Well Plate Ⅰ (Type U)

This is a sample well plate consisting of 96 500 μL, round-bottomed wells. (Sample well plate external dimensions are 128 x 86 mm. Sample well dimensions are shown in the figureon the right.)

This is a sample well plate consisting of 96 500 μL, round-bottomed wells. (Sample well plate external dimensions are 128 x 86 mm. Sample well dimensions are shown in the figureon the right.)- Made from high quality polypropylene.

- Well edges are higher than the surfaces of well plates, reducing the risk of contamination.

Well Caps

- Silicon caps designed specifically for use with Sample Well Plate Ⅰ (Type U) well plates. Automatically formseals around needles when pierced.

- Possess a unique structure which minimizes unsealing due to increases in well internal pressures.

Unique structure of well caps

When attaching well caps to well plates, air inside wells is released through the 4 slits located on the sides of well caps (see part A in the diagram above), thereby preventing increases in well internal pressures, the cause of cap unsealing. Complete sealing after attachment of well caps is achieved by the seal part B, also shown in the diagram above.

Elution tests for Sample Well Plate Ⅰ (Type U) and competitor’s well plate

HPLC mobile phase sealed in each well plate was analyzed after 24 hours to determine the presence or absence of eluted components.

Carry out blank tests to verify the presence or absence of elution components when using solutions containing organic solvents in this product.

Dispensing Tool for 96 Well Plates

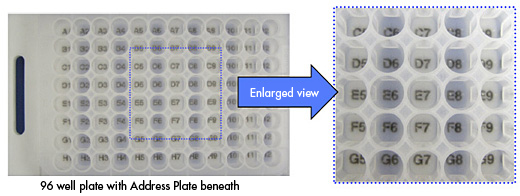

Address Plate®

This product displays well addresses at the bottom of 96 well plate wells, making manual dispensing easy.

Features

- Address Plates are placed beneath 96 well plates when performing manual dispensing. Addresses are clearly displayed at the bottom of wells, helping to prevent dispension of different solutions into the same well.

- Address Plates are made from acrylic resin. Addresses are printed using a special printing method making this a rugged, long-life product.

Notes:

Address Plates are designed for use only with round bottom micro-well plates. This product cannot be used with V bottom well plates. Please be aware that specifications and prices may change without prior notification due to product improvements.